Laipe, ile-iṣẹ wa gba iṣẹ kan. The customer's equipment for this project is a dissolving furnace with a temperature of 1300 ° C. Previously, the gas was pumped out and pretreated to measure oxygen. Because the temperature and pressure of the pumped gas have changed, the measured oxygen content is not the real-time oxygen content in the furnace, and the product quality cannot be controlled based on this oxygen content data.

Nitori imọ-ẹrọ idiwọn pataki ti ile-iṣẹ waIwadi atẹgun ti nerstgen, o le faagun awọn iwọn otutu to gaju ti 1400 ° C, nitorinaa o le fi sii taara sinu ina ileru ni 1300 ni 1300 akoonu ti atẹgun deede ninu ileru le ṣe iwọn ni akoko gidi laisi ilana asọtẹlẹ fifẹ.

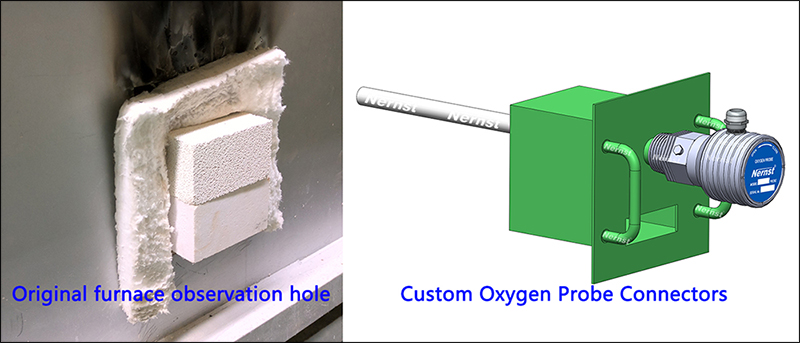

Sibẹsibẹ, ileru ti o wa ti alabara ko le tun ṣii lati fi sori ẹrọIwa-ẹni atẹgun giga ti Nerrngen giga. Our company specially designed and customized the oxygen probe connecting parts for the customer, without changing the original state of the furnace, which can not only meet the oxygen probe installation requirements, but also retain the original observation hole. Onibara jẹ itẹlọrun pupọ pẹlu agbara apẹrẹ apẹrẹ ile-iṣẹ wa ati iṣẹ ṣiṣe ọja.

Akoko ifiweranṣẹ: Oṣu Kẹsan-24-2024